Delivering quality

growing with customers

Striving to offer diverse one-stop service solutions through continuous.

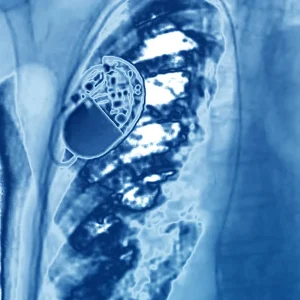

How it works

Key requirements for modern medical connectors

Computer connectors are widely used in many scenarios, including

Key requirements for modern medical connectors include:

Step 1 Be safe

When treating patients, the last thing they need to do is increase the risk. Although uncommon, there have been reports of serious injury or even death due to exposure to the conductors of medical connectors that are out of reach of human fingers. In terms of resolution, the IEC has proposed a standard that requires connectors used in medical applications to contain a form of insulation that prevents the human body from being shocked upon contact, further improving the safety of using modern medical devices.

Step 2: Reliability

As medical technology advances, so does the equipment used, and the professionals we rely on likewise rely on their equipment to function properly. Although connectors may seem like a trivial component in such a complex device, they play a vital role in the reliability of medical devices. When the connector is used as the connection point between the probe and its medical device during surgery, high expectations are placed on the reliability of the connector. In this way, the reliability of the connector can directly affect the success or failure of the surgery, which can save the patient's life or cause the patient to die. This is why the medical industry continues to invest in connectors that are proven to provide reliable performance over the life of the device.

Step 3: Constituent factors

Similar to smartphones, medical devices have size requirements. Thanks to recent advances in medicine, surgeons can now perform certain procedures with less invasiveness. Today's devices allow surgeons to perform complex procedures that require even opening a patient's body for long periods of time by simply creating a small incision, as large as opening a heart operation, large enough to insert a laparoscopic camera and can manipulate tools within the same narrow, ultra-high precision small incision. The success of these types of operations also depends on the complex set of components (such as connectors) in this medical device, as well as the ability of the surgical system to perform and optimize device functions that used to be cumbersome and laborious. Because they rely on surgeons, they are less precise, even more so.

Step 4: Speed

To help ensure the success of this minimally invasive medical procedure, surgeons also rely on images transmitted in real time from the laparoscopic camera inside the patient to the monitors they use to facilitate these types of surgeries. Today's connector technology allows high speed transmission of large amounts of data with high integrity, which greatly facilitates the success of such operations.

People who don't know much about connector functions may think of them as just another component in a medical device, but for those who depend on safety, reliability, form factor, and the speed of the instruments used, the right connector is critical.

Custom Order > Solution Communication > Software Simulation > Multi-Party Review > Finalize Design and Mold Making

Choose Fujinying 4 Reasons

Professional solution, customized

Experienced engineering team - Professional, efficient, reliable.

- Development focuses on customer needs, with dedicated engineers coordinating projects and conducting multi-angle design reviews;

- We use effective design tools like Pro-E, SolidWorks, AutoCAD, and ABAQUS;

- Our engineering team averages 10 years of experience in the connector industry;

- Automation is integrated into the product design phase to ensure quality and production capacity.

Full automation to ensure capacity

20 years of custom R&D for high-quality connectors, optimizing production lines.

- Over 500 automated assembly machines.

- Global automation design to free up labor and enhance efficiency.

- Minimized capacity drops from labor turnover.

- A team of skilled professionals continuously optimizes production lines and actively adopts automation technologies to improve capacity and quality.

Strict manufacturing processes

Widely recognized by many renowned global companies.

- Mitigate quality risks from the product design phase;

- Ensure quality through global automated production and data monitoring;

- Guarantee that every connector meets standards and customer requirements;

- Robust quality assurance system, complete testing equipment, and data-driven quality monitoring.

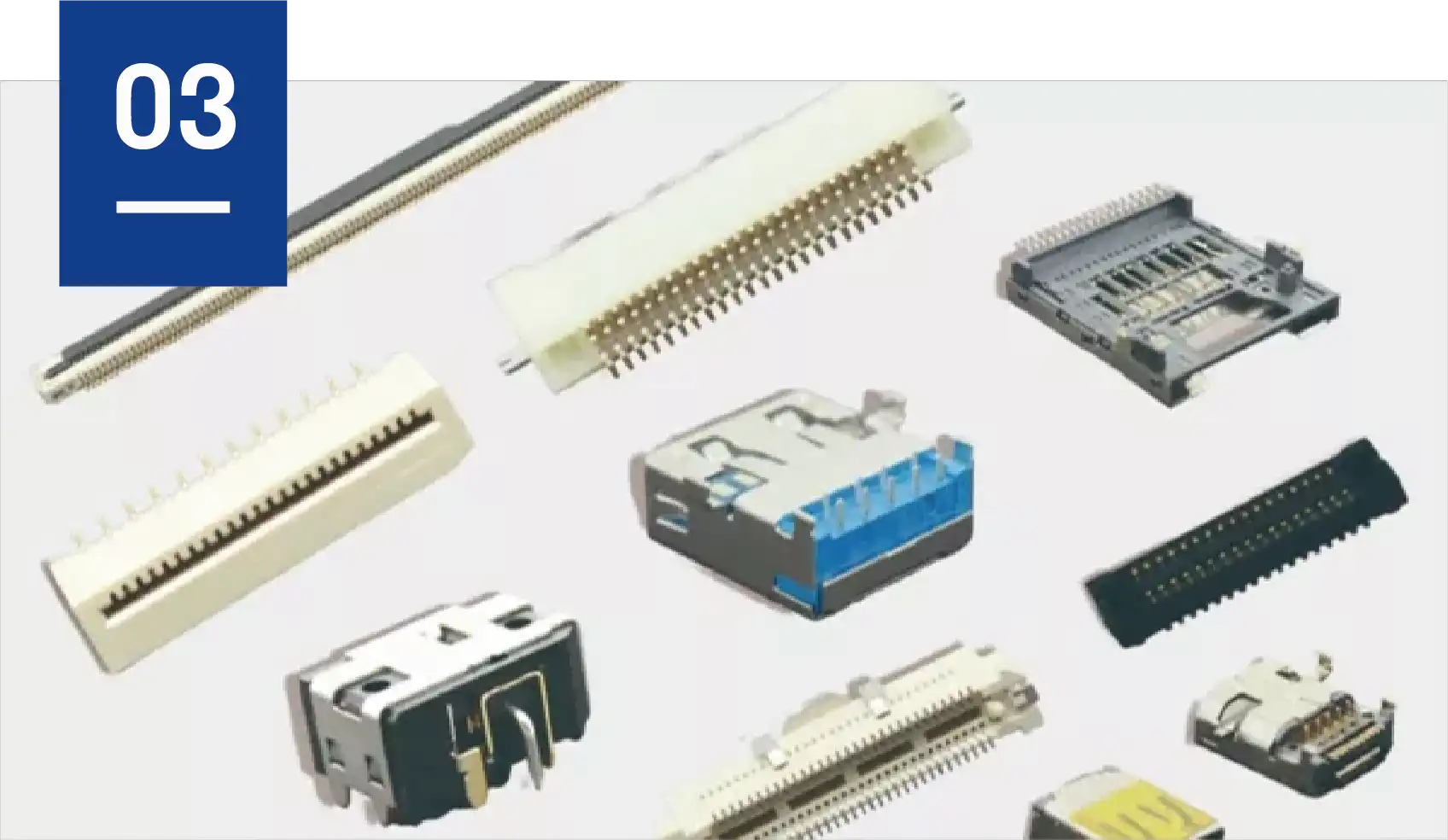

Wide variety, broad applications

Customizable to meet various needs, making one-stop connector procurement easy!

- 10 categories of connectors with over 50 series and thousands of models;

- Widely used in computers, communications, AI, digital products, audio-visual equipment, and security devices;

- Dedicated to creating a one-stop connector service system to be the most professional connector solution manufacturer.

Connector connections are trustworthy,Tell me what you want !

Shenzhen Fuyinjing Electronics Co., Ltd.

is a leading connector manufacturer committed to providing high-quality solutions.