Delivering quality

growing with customers

Striving to offer diverse one-stop service solutions through continuous.

How it works

What is the structure and purpose of the aviation plug connector?

Computer connectors are widely used in many scenarios, including

Overview

Aviation plug connector in our daily life may be in contact with less, but with the development of science and technology, the future application of this connector will be more and more extensive, this article will introduce you to the structure of the aviation plug connector, use.

The aviation plug connector, also known as the aviation cable connector, is a device for the cable connection of avionics, they are commonly used in aircraft, missiles, satellites and other aviation and aerospace applications to connect control signals, power and data lines. These connectors need to have reliability and vibration resistance to meet the operating needs of harsh operating environments and extreme conditions, common aviation plug connectors include the LPC series of Odu in Germany, the D* series of ITT Cannon in the United States, the 8525 series of Souriau in France.

First, the structure of the aviation plug connector

The structure of the aviation plug connector is very complex, usually including the following components:

1. Plug housing

The plug shell is the main part of the aviation plug connector, usually made of high-strength metal materials, the design structure of the shell is usually made of environmentally friendly materials, which can protect the wire connector, but also conducive to the maintenance and update of the cable.

2. Plug adapter

The plug adapter is the core part of signal transmission, and its design structure requires high precision, and high precision and stability when inserting the plug adapter. Plug adapters are generally divided into two types, respectively riveted and welded, plug adapters using riveted type connectors can reduce the resistance of the wire and improve the quality of the signal, but it requires certain technical requirements and operational skills.

3. Plug protection cover

The plug protection cover mainly protects the plug adapter to avoid damage to the joint caused by external factors, in general, the protective cover needs to have the function of rain, dust and radiation protection, and to have good corrosion resistance.

Second, the use of aviation plug connectors

1. Waterproof

Aircraft flying high in the atmosphere may encounter natural weather such as rain and snow, so it is necessary to use a connector with good waterproof performance, and the aviation plug connector is designed to be the connector most suitable for this need in commercial aviation products, usually with a high degree of waterproof performance.

2. Mechanical strength

When the aircraft is subjected to external impact or collision, the connector must have good mechanical strength to ensure that it can maintain a stable connection, and the aviation plug connector can provide a connection with a high degree of mechanical strength, so as to avoid loosening and failure of the connection.

Custom Order > Solution Communication > Software Simulation > Multi-Party Review > Finalize Design and Mold Making

Choose Fujinying 4 Reasons

Professional solution, customized

Experienced engineering team - Professional, efficient, reliable.

- Development focuses on customer needs, with dedicated engineers coordinating projects and conducting multi-angle design reviews;

- We use effective design tools like Pro-E, SolidWorks, AutoCAD, and ABAQUS;

- Our engineering team averages 10 years of experience in the connector industry;

- Automation is integrated into the product design phase to ensure quality and production capacity.

Full automation to ensure capacity

20 years of custom R&D for high-quality connectors, optimizing production lines.

- Over 500 automated assembly machines.

- Global automation design to free up labor and enhance efficiency.

- Minimized capacity drops from labor turnover.

- A team of skilled professionals continuously optimizes production lines and actively adopts automation technologies to improve capacity and quality.

Strict manufacturing processes

Widely recognized by many renowned global companies.

- Mitigate quality risks from the product design phase;

- Ensure quality through global automated production and data monitoring;

- Guarantee that every connector meets standards and customer requirements;

- Robust quality assurance system, complete testing equipment, and data-driven quality monitoring.

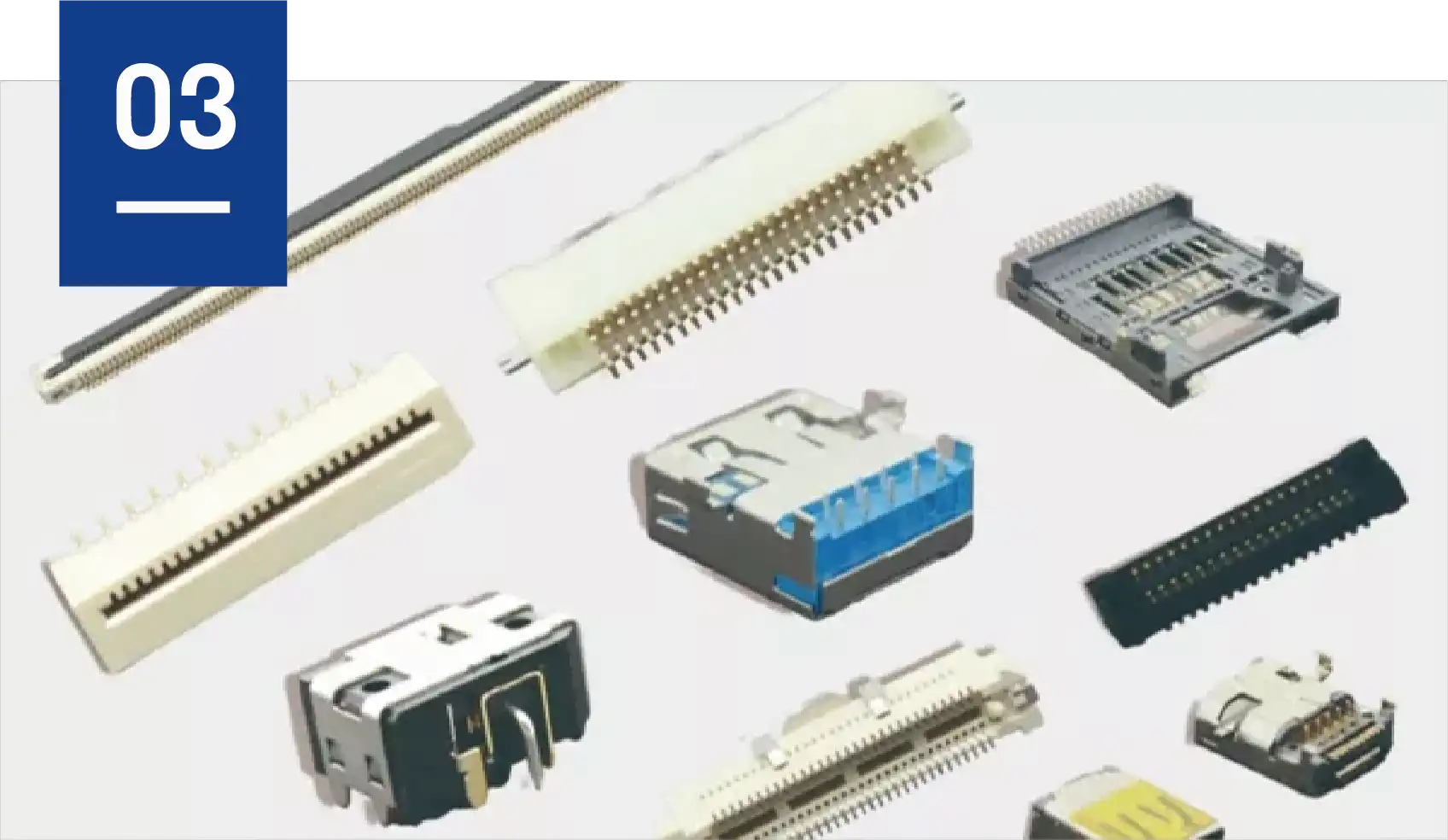

Wide variety, broad applications

Customizable to meet various needs, making one-stop connector procurement easy!

- 10 categories of connectors with over 50 series and thousands of models;

- Widely used in computers, communications, AI, digital products, audio-visual equipment, and security devices;

- Dedicated to creating a one-stop connector service system to be the most professional connector solution manufacturer.

Connector connections are trustworthy,Tell me what you want !

Shenzhen Fuyinjing Electronics Co., Ltd.

is a leading connector manufacturer committed to providing high-quality solutions.