Delivering quality

growing with customers

Striving to offer diverse one-stop service solutions through continuous.

How it works

The importance of connectors in industrial robots

Computer connectors are widely used in many scenarios, including

The space on the production line is becoming more and more compact, and the robot is becoming more and more miniaturized, especially when the robot works in a high temperature environment and has special requirements for connection technology in a harsh environment, the role of the connector is more important. According to different needs, connectors are mainly used in the following situations of industrial robots:

Highly integrated interfaces save space for robots

In developing new applications, such as on the assembly line, robot manufacturers face two major challenges:

Robots need more and more sensory sensors, and they must become smaller and more flexible for more complex assembly operations.

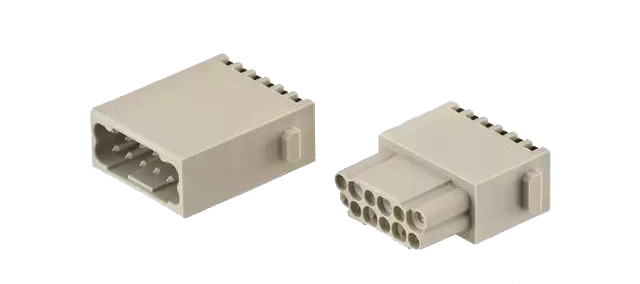

High-density interface connectors with mixed configurations

In addition to telecommunications numbers, modular connectors can transmit compressed air, light waves and high currents. As a "hybrid" interface, they accomplish the tasks of several small individual interfaces.

Custom Order > Solution Communication > Software Simulation > Multi-Party Review > Finalize Design and Mold Making

Choose Fujinying 4 Reasons

Professional solution, customized

Experienced engineering team - Professional, efficient, reliable.

- Development focuses on customer needs, with dedicated engineers coordinating projects and conducting multi-angle design reviews;

- We use effective design tools like Pro-E, SolidWorks, AutoCAD, and ABAQUS;

- Our engineering team averages 10 years of experience in the connector industry;

- Automation is integrated into the product design phase to ensure quality and production capacity.

Full automation to ensure capacity

20 years of custom R&D for high-quality connectors, optimizing production lines.

- Over 500 automated assembly machines.

- Global automation design to free up labor and enhance efficiency.

- Minimized capacity drops from labor turnover.

- A team of skilled professionals continuously optimizes production lines and actively adopts automation technologies to improve capacity and quality.

Strict manufacturing processes

Widely recognized by many renowned global companies.

- Mitigate quality risks from the product design phase;

- Ensure quality through global automated production and data monitoring;

- Guarantee that every connector meets standards and customer requirements;

- Robust quality assurance system, complete testing equipment, and data-driven quality monitoring.

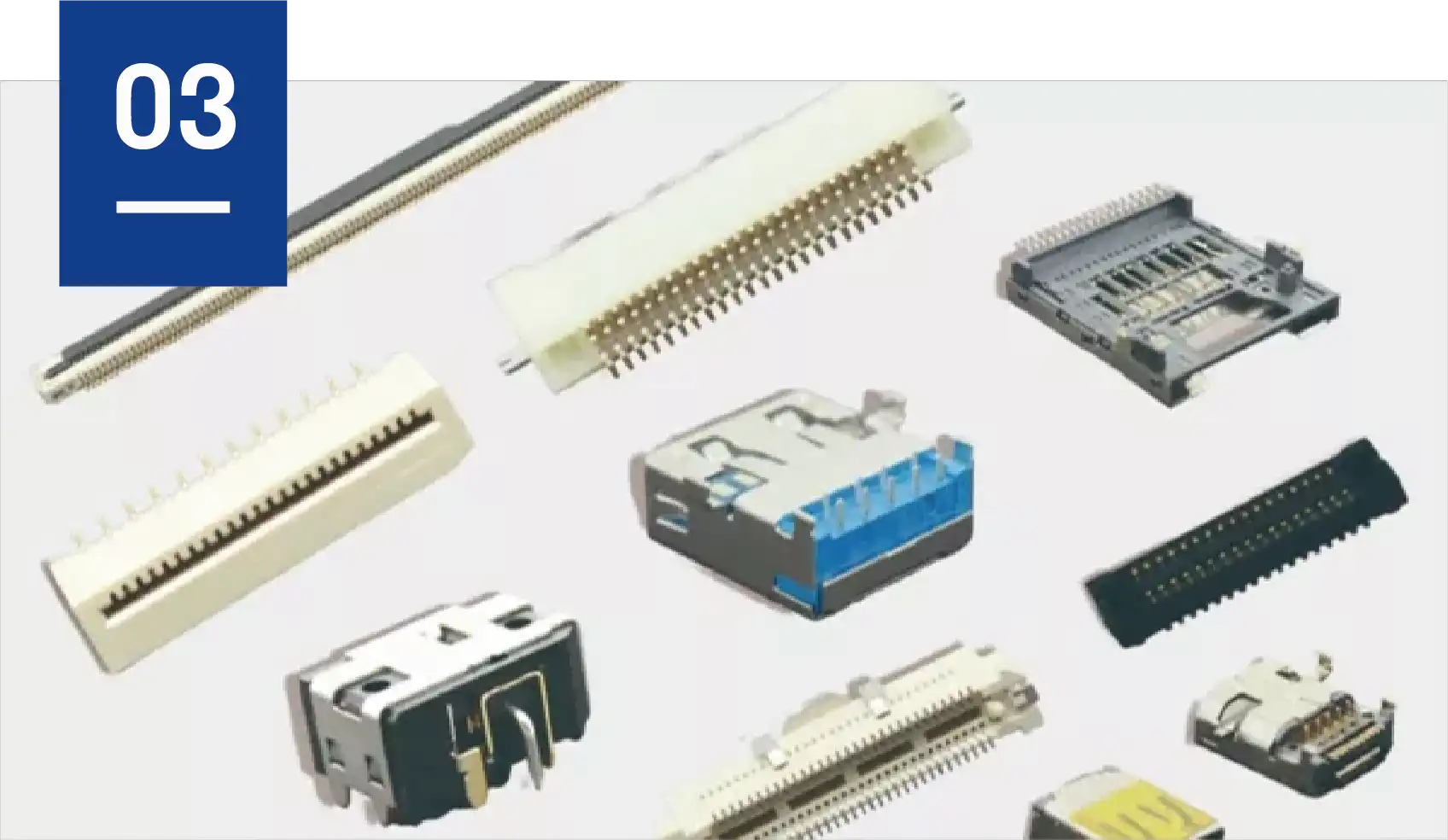

Wide variety, broad applications

Customizable to meet various needs, making one-stop connector procurement easy!

- 10 categories of connectors with over 50 series and thousands of models;

- Widely used in computers, communications, AI, digital products, audio-visual equipment, and security devices;

- Dedicated to creating a one-stop connector service system to be the most professional connector solution manufacturer.

Connector connections are trustworthy,Tell me what you want !

Shenzhen Fuyinjing Electronics Co., Ltd.

is a leading connector manufacturer committed to providing high-quality solutions.