Delivering quality

growing with customers

Striving to offer diverse one-stop service solutions through continuous.

How it works

What is a USB connector?

Computer connectors are widely used in many scenarios, including

Overview

USB is popular due to its compatibility with numerous platforms and operating systems, low implementation costs, and ease of use. Connectors come in a variety of shapes and sizes with a variety of functions.

USB (Universal Serial Bus) is an industry standard developed in the 1990s for connections between computers and peripherals. USB is popular due to its compatibility with numerous platforms and operating systems, low implementation costs, and ease of use.

Usb-if (Universal Serial Bus Implemutors Forum, Inc.) is the support organization and forum for the advancement and adoption of USB technology. It was founded by the company that developed the USB specification and has more than 700 member companies. Current board members include Apple Inc., Hewlett-Packard Co., Intel Corp., Microsoft Corp., Renesas Electronics, ST and Texas Instruments.

Each USB connection is made using two connectors: an outlet (or socket) and a plug. The USB specification addresses the physical interfaces and protocols for device connectivity, data transmission, and power supply. USB connector types are represented by letters that indicate the physical shape of the connector (A, B, and C) and numbers that indicate the speed of data transfer (e.g. 2.0, 3.0, 4.0). The bigger the number, the faster the speed.

Specifications -- Letters

USB A is thin and rectangular. It is probably the most common type and is used to connect laptops, desktops, media players, and game consoles. They are primarily used to allow host controllers or hub devices to provide data or power to smaller devices (peripherals and accessories).

USB B is square with a beveled top. It is used by printers and external hard drives to send data to host devices.

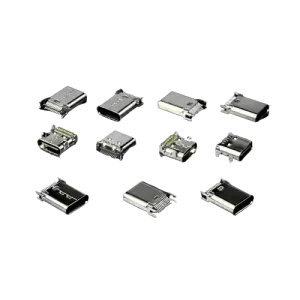

USB C is the latest type. It is small, has an elliptical shape and rotational symmetry (can be connected in either direction).

USB C transmits data and power over a single cable. It has been so widely accepted that the European Union will require its use for battery charging starting in 2024.

Specifications - Numbers

The original specification, USB 1.0 (12 Mb/s), was released in 1996, and USB 2.0 (480 Mb/s) in 2000. Both are suitable for USB Class A connectors.

With USB3.0, naming conventions become more complex.

USB 3.0 (5 Gb/s), also known as USB 3.1 Gen 1, came out in 2008. It is currently known as USB 3.2 Gen 1 and works with USB Type A and USB Type C connectors.

Introduced in 2014, USB 3.1 or USB 3.1 Gen 2 (10 Gb/s), currently known as USB 3.2 Gen 2 or USB 3.2 Gen 1×1, works with USB Type A and USB Type C.

USB 3.2 Gen 1 x 2 (10 Gb/s) for USB Type C. This is the most common specification for USB Type C connectors.

USB 3.2 (20 Gb/s) came out in 2017 and is currently known as USB 3.2 Gen 2×2. This applies to USB type C.

(USB 3.0 is also known as SuperSpeed.)

USB4 (usually without Spaces before 4) came out in 2019 and is widely available by 2021. The USB4 standard is up to 80 Gb/s, but currently its top speed is 40 Gb/s. USB 4 is suitable for USB type C.

Custom Order > Solution Communication > Software Simulation > Multi-Party Review > Finalize Design and Mold Making

Choose Fujinying 4 Reasons

Professional solution, customized

Experienced engineering team - Professional, efficient, reliable.

- Development focuses on customer needs, with dedicated engineers coordinating projects and conducting multi-angle design reviews;

- We use effective design tools like Pro-E, SolidWorks, AutoCAD, and ABAQUS;

- Our engineering team averages 10 years of experience in the connector industry;

- Automation is integrated into the product design phase to ensure quality and production capacity.

Full automation to ensure capacity

20 years of custom R&D for high-quality connectors, optimizing production lines.

- Over 500 automated assembly machines.

- Global automation design to free up labor and enhance efficiency.

- Minimized capacity drops from labor turnover.

- A team of skilled professionals continuously optimizes production lines and actively adopts automation technologies to improve capacity and quality.

Strict manufacturing processes

Widely recognized by many renowned global companies.

- Mitigate quality risks from the product design phase;

- Ensure quality through global automated production and data monitoring;

- Guarantee that every connector meets standards and customer requirements;

- Robust quality assurance system, complete testing equipment, and data-driven quality monitoring.

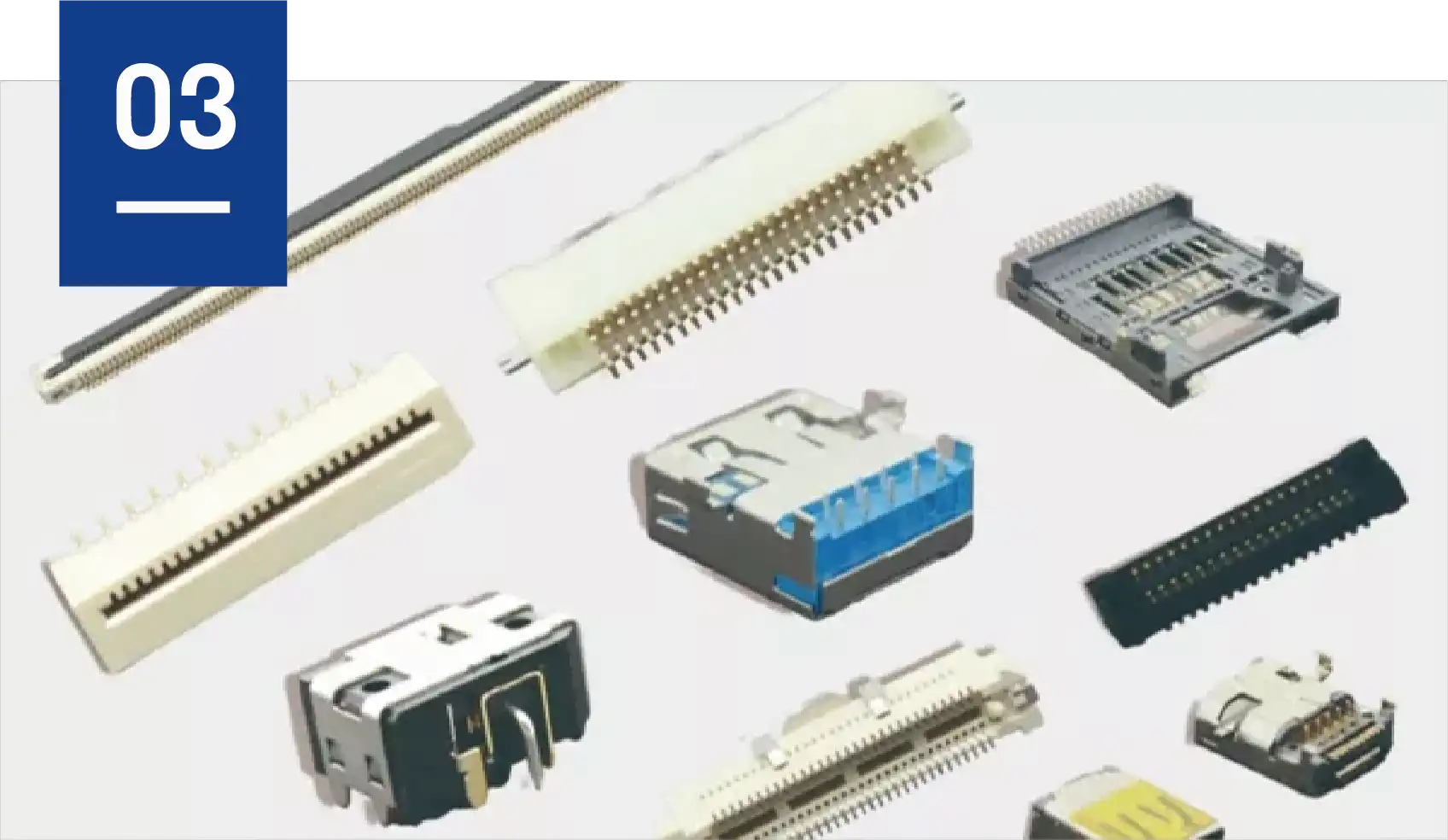

Wide variety, broad applications

Customizable to meet various needs, making one-stop connector procurement easy!

- 10 categories of connectors with over 50 series and thousands of models;

- Widely used in computers, communications, AI, digital products, audio-visual equipment, and security devices;

- Dedicated to creating a one-stop connector service system to be the most professional connector solution manufacturer.

Connector connections are trustworthy,Tell me what you want !

Shenzhen Fuyinjing Electronics Co., Ltd.

is a leading connector manufacturer committed to providing high-quality solutions.