Delivering quality

growing with customers

Striving to offer diverse one-stop service solutions through continuous.

How it works

High-speed connector selection.

Computer connectors are widely used in many scenarios, including

Overview

Communication is a system engineering, the performance of the various components used will affect the performance of the entire network, of which the communication connector belongs to the network transmission media interconnection equipment, the performance of the connector used may affect the entire communication system. Optical fiber connectors are used in the communication neighborhood, and there are many models and standards of connector products at present. At the same time, new processes and new technologies emerge in an endless stream. Therefore, users should choose the appropriate connector according to their actual situation. The relevant technical personnel of communication network construction should also be familiar with and understand the performance of various connectors, consider the construction cost and hardware upgrade of the network to the high-speed network upgrade, put forward the interface requirements, and comprehensively consider the performance, price and development of the connector, and reasonably select the connector.

The form and structure of connectors are ever-changing, and there are various forms of connectors with different application objects, frequencies, power and application environments. As a kind of physical layer device, communication connector affects the reliability and performance of transmission system to some extent. At the same time, the improvement of connector connection technology simplifies terminal connection and maintenance services, reduces the need for hard wire connections, makes the design and production process more convenient and flexible, and reduces production and maintenance costs. Since the optical fiber connector is also a lossy product, it is also required to be cheap.

The role of the fiber connector is to precisely dock the two end faces of the fiber, so that the light energy output of the transmitting fiber can be coupled to the receiving fiber to the maximum extent, and the impact on the system due to the access to the optical link itself is minimized, which is also the basic requirements of the fiber connector. The optical fiber connector here is exactly the optical fiber active connector, commonly known as the live connector, which is classified according to whether the optical fiber connector is removable or not; Accordingly, there is also a non-removable connector, called a fixed connector. It is precisely because of the use of connectors that the detachable connection between optical channels is possible, thus facilitating the commissioning and maintenance of the optical system, and making the switching scheduling of the optical system more flexible.

Custom Order > Solution Communication > Software Simulation > Multi-Party Review > Finalize Design and Mold Making

Choose Fujinying 4 Reasons

Professional solution, customized

Experienced engineering team - Professional, efficient, reliable.

- Development focuses on customer needs, with dedicated engineers coordinating projects and conducting multi-angle design reviews;

- We use effective design tools like Pro-E, SolidWorks, AutoCAD, and ABAQUS;

- Our engineering team averages 10 years of experience in the connector industry;

- Automation is integrated into the product design phase to ensure quality and production capacity.

Full automation to ensure capacity

20 years of custom R&D for high-quality connectors, optimizing production lines.

- Over 500 automated assembly machines.

- Global automation design to free up labor and enhance efficiency.

- Minimized capacity drops from labor turnover.

- A team of skilled professionals continuously optimizes production lines and actively adopts automation technologies to improve capacity and quality.

Strict manufacturing processes

Widely recognized by many renowned global companies.

- Mitigate quality risks from the product design phase;

- Ensure quality through global automated production and data monitoring;

- Guarantee that every connector meets standards and customer requirements;

- Robust quality assurance system, complete testing equipment, and data-driven quality monitoring.

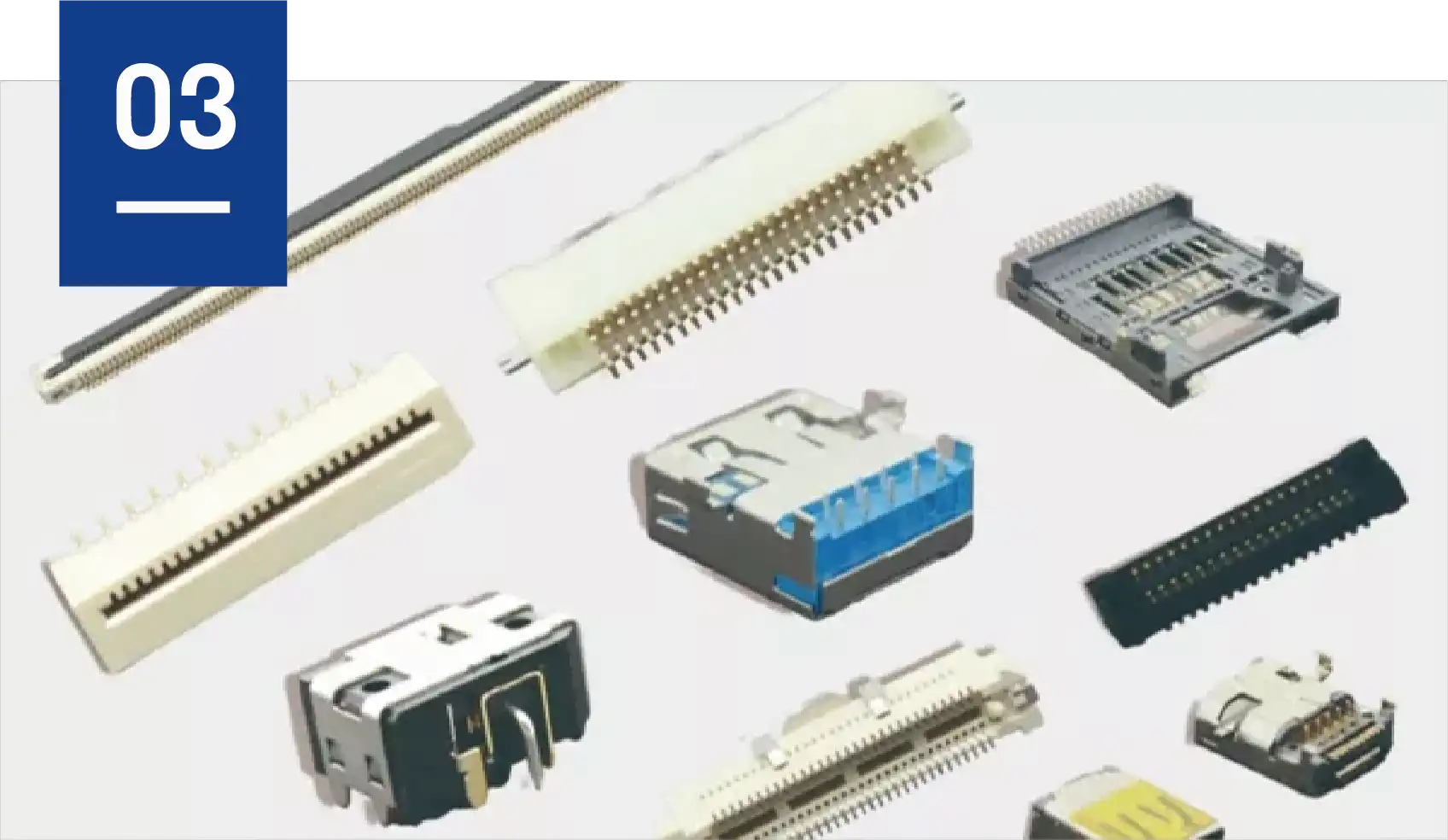

Wide variety, broad applications

Customizable to meet various needs, making one-stop connector procurement easy!

- 10 categories of connectors with over 50 series and thousands of models;

- Widely used in computers, communications, AI, digital products, audio-visual equipment, and security devices;

- Dedicated to creating a one-stop connector service system to be the most professional connector solution manufacturer.

Connector connections are trustworthy,Tell me what you want !

Shenzhen Fuyinjing Electronics Co., Ltd.

is a leading connector manufacturer committed to providing high-quality solutions.